SAE Alloy 52Enquiry|Print this page

| Category | Type | Steel grade | Standard | Country |

|---|---|---|---|---|

| Grades | Special Alloy | Alloy 52 | SAE | USA |

Chemical composition%of the ladle analysis of gradeAlloy 52

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Al(%) | Other(%) |

|---|---|---|---|---|---|---|---|---|

| 0.05 | 0.30 | 0.60 | 0.025 | 0.025 | 0.25 | 50.5 | 0.10 | Iron:Balance |

STRIP, FOIL & WIRE, ASTM F30

Applications

Applications for Alloy 52 include magnetic reed switches and seals that need controlled linear expansion to approximately 977°F (525 °C)

Description

Alloy 52 is a 50.50% nickel-iron alloy developed for glass-to-metal seals for some of the soft glasses and some ceramics. The alloy’s rate of thermal expansion is virtually constant to a temperature of about 1050°F (565°C).

Chemistry Typical

Carbon: 0.05 max

Silicon: 0.30 max

Manganese: 0.60 max

Nickel: 50.5 nom

Chromium: 0.25 max

Iron: Balance

Phosphorus: 0.025 max

Sulfur: 0.025 max

Aluminum: 0.10 max

Physical Properties

Density: 0.30 lb/in3, 8.30 g/cm3

Electrical Resistivity: ohm-cir-mil/ft, microhm-cm:

At 68°F (20°C): 258(43)

Thermal Conductivity: BTU-in/hr-ft2-°F (W/m•K):

68-212°F (20-100°C): 97(140)

Mean Coefficient of Thermal Expansion: µin/in-°F (µm/m-°C):

77-842°F (25-450°C): 5.4 (9.8)

Melting Range: 2600°F (1430°C)

Forms

Coil: Sheet, Strip, Ribbon

Wire – Profile, Round, Flat, Square

Mechanical Properties at Room Temperature

Properties: Annealed Typical Ultimate Tensile Strength: 78 KSI nom (536 MPa nom)

Yield Strength: 35 KSI nom (240 MPa nom) Elongation: 30% nom

Hardness: Rb 73 nom

Properties: Tempered Alloy 52 can be cold worked to various tempers. Contact Ulbrich Technical Service for additional information

Additional Properties

Corrosion Resistance Refer to NACE (National Association of Corrosion Engineers) for recommendations.

Finishes

#1 – Hot rolled annealed and descaled. It is available in strip, foil and ribbon. It is used for applications where a smooth decorative finish is not required. # 2D – Dull finish produced by cold rolling, annealing and descaling. Used for deep drawn parts and those parts that need to retain lubricants in the forming process. # 2B –Smooth finish produced by cold rolling, annealing and descaling. A light cold rolling pass is added after anneal with polished rolls giving it a brighter finish than 2D. #BA Bright annealed cold rolled and bright annealed #CBA Course bright annealed cold rolled matte finish and bright anneal #2 Cold Rolled # 2BA – Smooth finish produced by cold rolling and bright annealing. A light pass using highly polished rolls produces a glossy finish. A 2BA finish may be used for lightly formed applications where a glossy finish is desired in the formed part. Polished – Various grit finish for specific polish finished requirements

* Not All Finishes are Available for All Alloys – Consult Sales for Applicable Finishes

Wire Finishes

XC-Extra clean. Bright annealed or bright annealed and cold rolled

Grease-Ultra bright finish for decorative applications

Soap-Soap is not removed from tempered wire to act as a lubricant.

* Contact Ulbrich Wire with special finish requests.

Heat Treatment Alloy 52 is non hardenable by heat treatment.

Welding For best results refer to: SSINA’s “Welding of Stainless Steels and Other Joining Methods”.

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

|---|---|---|---|---|---|---|

| 113(≥) | 872(≥) | 12 | 12 | 31 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 344 |

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 | Expansion rate |

|---|---|---|---|---|---|---|---|

| 647(≥) | 681(≥) | 41 | 32 | 22 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 344 | |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | |||||

| 246 | 812 | 686 |

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging,hot rolling and cold rolling | Annealed,Solution and Aging,Q+T,ACID-WASHED,Shot Blasting |

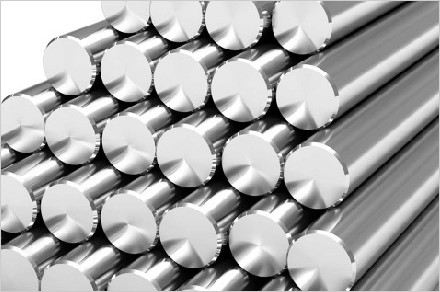

| Steel Bar | Round Bar,Flat Bar,Square Bar | Φ8-1200mm*L | Forging,hot rolling and cold rolling,Cast | Black,Rough Turning,Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed,Solution and Aging,Q+T,ACID-WASHED,Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes,Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion,Cold Drawn,Welded | Annealed,Solution and Aging,Q+T,ACID-WASHED |

| Grade | Standard | Country | Application |

|---|---|---|---|

| FERRALIUM alloy 255 | SAE | USA | FERRALIUM alloy 255 |

| S32550 | SAE | USA | Duplex (Austenitic-Ferritic) Chromium Nickel Molybdenum Copper Nitrogen Stainless Steel |

| Alloy 713C | SAE | USA | HIGH-TEMPERATURE HIGH-STRENGTH NICKEL BASE ALLOYS,CAST ALLOYS |

| 2.4605 | SAE | USA | The chemically stable and high-temperature resistant nickel and cobalt alloy 2.4605 (alloy 59) is mainly used in the chemical industry, flue gas desulphurating plants, paper industry. |

| Alloy 59 | SAE | USA | The chemically stable and high-temperature resistant nickel and cobalt alloy 2.4605 (alloy 59) is mainly used in the chemical industry, flue gas desulphurating plants, paper industry. |

| NiCr23Mo16Al | SAE | USA | The chemically stable and high-temperature resistant nickel and cobalt alloy 2.4605 (alloy 59) is mainly used in the chemical industry, flue gas desulphurating plants, paper industry. |

| ALLOY 301 | SAE | USA | An age-hardened alloy that combines the excellent corrosion resistance characteristics of Nickel 200 with the added advantages of greater strength and hardness. |

| Nicrofer 3718 So* - Alloy DS* | SAE | USA | Nicrofer 3718 So* - Alloy DS* |

| Nicrofer 5520 Co B - Alloy 617 B | SAE | USA | Nicrofer 5520 Co B - Alloy 617 B |

| INCONEL® alloy MA 758 | SAE | USA | It is used in a range of thermal processing applications, from furnace components, such as hearth rollers, to jigs, tools, and other fabrications for supporting workpieces through heat-treatment processes. It has been specified for a fuel atomizer applica |

| Nitronic 60®, UNS S21800, Alloy 218 | SAE | USA | used in the chemical, petrochemical, pharmaceutical, machine industries (hydraulic systems) and food industry for valves, flanges, pump parts, springs, heat exchangers, screws and even chains. |

| X1NiCrMoCu31-27-4, 1.4563, Alloy 28, UNS N08028 | SAE | USA | Seamless circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Austenitic steel designed to deal with sour gas, phosphoric, sulphuric and acetic acids, and vinyl chloride. It is used for heat exchangers, co |

| X1NiCrMoCuN25-20-7, 1.4529, Alloy 926, UNS N08926 | SAE | USA | Steel is used mainly in the chemical, paper, cryogenic, aerospace, and power industries. The main end products are heat exchangers, chemical tanks, pumps, screws, aircraft components, bushings, shafts, water desalination and flue gas desulphurisation equi |

| A 240 Type XM-21 | SAE | USA | Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications |

| A 276 XM-21 | SAE | USA | Stainless Steel Bars and Shapes |

| A 959 Type XM-21 | SAE | USA | Standard Guide for Specifying Harmonized Standard Grade Compositions for Wrought Stainless Steels |

| SA-276 XM-21 | SAE | USA | Specification for Stainless Steel Bars and Shapes |

| XM-21 | SAE | USA | Chemical compositions of SAE wrought stainless steels |

| A 240 S30452 | SAE | USA | Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications |

| A 276 S30452 | SAE | USA | Stainless Steel Bars and Shapes |