15-5PH,1.4545,X5CrNiCuNb15-5,S15500 Enquiry | Print this page

ASTM 15-5PH,1.4545,X5CrNiCuNb15-5,S15500 Details

ASTM 15-5PH,1.4545,X5CrNiCuNb15-5,S15500 Standard Download

| Category | Type | Grade | Microstructure | Designations |

|---|---|---|---|---|

| Grades | Stainless Steels | 15-5PH,1.4545,X5CrNiCuNb15-5,S15500 | Martensite | USA - ASTM , SAE AMS 5346C (2006) - Steel, Corrosion-Resistant, Investment Castings 15Cr - 4.6Ni - 0.22Cb (Nb) - 2.8Cu Solution and Precipitation Heat Treated (H925) 180 ksi (1241 MPa) Tensile Strength (15-5) SAE AMS 5347B (2006) - Steel, Corrosion-Resistant, Investment Castings 15Cr - 4.6Ni - 0.22Cb (Nb) - 2.8Cu Solution and Precipitation Heat Treated (H1000) 150 ksi (1034 MPa) Tensile Strength (15-5) SAE AMS 5357C (2011) - Steel, Corrosion Resistant, Investment Castings 15Cr - 4.6Ni - 0.22Cb - 2.8Cu Solution Heat Treated, Precipitation Hardenable SAE AMS 5400B (2007) - Steel, Corrosion-Resistant, Investment Castings 15Cr - 4.6Ni - 0.22Cb - 2.8Cu Solution and Precipitation Heat Treated (H935) 170 ksi (1172 MPa) Tensile Strength SAE AMS 5659N (2012) - Steel, Corrosion-Resistant, Bars, Wire, Forgings, Rings, and Extrusions 15Cr - 4.5Ni - 0.30CB (Nb) - 3.5Cu Consumable Electrode Melted Solution Heat Treated, Precipitation Hardenable |

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | - | 0.07 | ||

| Si | - | 0.10 | ||

| Mn | - | 0.70 | ||

| Cr | 14.50 | 15.50 | ||

| Ni | 4.5 | 5.5 | ||

| Cu | 2.5 | 3.20 | ||

| P | - | 0.035 | ||

| S | - | 0.030 | ||

| Nb | 0.15 | 0.35 | ||

| N | - | 0.05 |

Mechanical properties of grade 15-5PH,1.4545,X5CrNiCuNb15-5,S15500 SAE AMS 5346C (2006)

Yield Strength,Rp 0.2(MPa)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| H900 | 1000 | |||

| H925 | 1035 | |||

| H1025 | 965 | |||

| H1075 | 795 | |||

| H1100 | 760 | |||

| H1150 | 670 |

Tensile Strength,Rm(MPa)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| H900 | 1170 | |||

| H925 | 1205 | |||

| H1025 | 1035 | |||

| H1075 | 1000 | |||

| H1100 | 930 | |||

| H1150 | 860 |

Impact,Kv/Ku(J)

| Condition | Min | Max | Similar | Note |

|---|

Elongation,A(%)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| H900 | 5 | |||

| H925 | 5 | |||

| H1025 | 9 | |||

| H1075 | 9 | |||

| H1100 | 9 | |||

| H1150 | 10 |

Reduction of area,(%)

| Condition | Min | Max | Similar | Note |

|---|

Hardness

| Condition | Type | Min | Max | Similar | Note |

|---|---|---|---|---|---|

| H900 | HB | 375 | |||

| H925 | HB | 375 | |||

| H1025 | HB | 311 | |||

| H1075 | HB | 277 | |||

| H1100 | HB | 269 | |||

| H1150 | HB | 269 | |||

| H1150M | HB | 310 | |||

| H1150DBL | HB | 310 |

Related properties

| Application - 15-5 PH is a high-alloy, stainless, precipitation hardened steel with martensitic structure. It is characterized by excellent mechanical properties - strength and hardness, and at the same time excellent corrosion resistance. |

High temperature alloys and other special alloys.

Martensitic stainless construction steel 15-5PH, 1.4545, UNS S15500, X5CrNiCuNb15-5 precipitation hardened, used in the aviation industry according to SA 564, SA 693, A705.

Similar Steel Grades

AMS 5346, AMS 5347, AMS 5348, AMS 5356, AMS 5357, AMS 5400, A747 TYPE 15-5, J92110, SA 747 TYPE 15-5, CB7CU-2, A959 GRADE XM-12, 15CR-5NI, 15-5 ,15-5PH, 15-5 PH, UNS S15500, AMS 5658, AMS 5659, AMS 5826, AMS 5862, AMS 5750, A 564 TYPE XM-12, A 694 GRADE XM-12, A 705 GRADE XM-12, 1.4545, X5CRNICUNB15-5, X3CRNICUNB15-5-4, ACIDUR 4545, N701, SF 15/5, 05CR15NI5CU4NB, Z5CNU15-05, EZ7CNU15.05, Z 5 CNU 15-05. See our offer Non-alloy carbon steel Case-hardening steel Throught hardening steel Alloy and carbon spring steel Corrosion resistant stainless steel Heat-resistant steel and valve steel Boiler steel for high temperature applications Bearing steel Alloy construction nitriding steel Hadfield Steel - high-manganese hard-wearing austenitic Alloy and carbon Tool steels HSS High-speed steels Maraging steel Aviation and aero steel - AIR 9160C

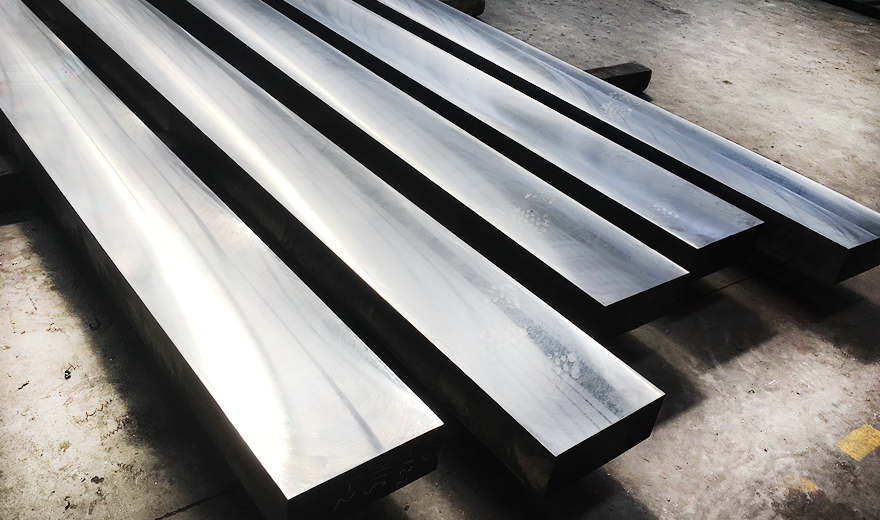

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

| Grade | Standard | Country | Application |

|---|---|---|---|

| A 564 S15500 | SAE | USA | Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes |

| A 693 S15500 | SAE | USA | Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip |

| A 705 S15500 | SAE | USA | Age-Hardening Stainless Steel Forgings |

| S15500 | AISI | USA | Precipitation Hardenable Chromium Nickel Copper Stainless Steel |

| SA-564 S15500 | AMS | USA | Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes |

| SA-693 S15500 | AMS | USA | Specification for Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip |

| SA-705 S15500 | AMS | USA | Specification for Age-Hardening Stainless Steel Forgings |

| A 564 XM-12 | SAE | USA | Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes |

| A 693 Type XM-12 | SAE | USA | Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip |

| A 705 XM-12 | SAE | USA | Age-Hardening Stainless Steel Forgings |

| A 959 Type XM-12 | SAE | USA | Standard Guide for Specifying Harmonized Standard Grade Compositions for Wrought Stainless Steels |

| SA-564 XM-12 | AMS | USA | Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes |

| SA-693 Type XM-12 | AMS | USA | Specification for Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip |

| SA-705 Type XM-12 | AMS | USA | Specification for Age-Hardening Stainless Steel Forgings |

| 15-5PH | ASTM | USA | High temperature alloys and other special alloys |

| 15-5PH,1.4545,X5CrNiCuNb15-5,S15500 | ASTM | USA | High temperature alloys and other special alloys |

| Y1Cr18Ni9 | GB | China | Improve the machinability, ablation resistance. Suitable for automatic lathe production of bolt and nut |

| 1Cr18Ni9 | GB | China | High strength after cold forming, but elongation than 1 cr17ni7 slightly worse. Used in architectural decoration parts |

| 1Cr18Mn10Ni5Mo3N | GB | China | Of urea with good corrosion resistance, can produce urea corrosion of the equipment. |

| 1Cr17Ni7 | GB | China | High strength after cold forming. Used in railway vehicle, conveyor belt, bolt and nut, etc |

Relevant products

-

AMS 5659 15-5PH forged Flat Bar

-

SKD-11 Cold working die steel

-

X165CrMoV12 Cold working die steel

-

17-4ph steel wire

-

T30402/X155CrVMo121 Die Steel Sheet

-

1.4980 Round Bar

-

DT413 / 4Cr5MoSiV1MOD

-

1.4980

-

45Cr14Ni14W2Mo forging

-

GH 3536 Sheet

-

UNS NO7718 Coil/Strip/Sheet

-

UNS N10276 Coil

-

X65Cr13 profile steel

-

4145H Hollow Bar

-

IncoloyA-286 / GH 2132

-

Inconel718 round bar

-

Inconel601 round bar

-

ERNiMo-10 round bar

-

ERNi-1 wire

-

Incoloy800 round bar

15-5PH,1.4545,X5CrNiCuNb15-5,S15500 Steel Stock

| Steel grade | Dimension | Shape | Unit | Quantity | Delivery state | Query |

|---|---|---|---|---|---|---|

| 15-5PH Forgrd Flat Bar | Select | 0 | Select | Enquiry | ||

| SkD-11 Round Bar Stock | Φ30-Φ350 | Round Bar | Kgs | 3102 | Hot-Rolled+Annealed+black | Enquiry |

| 17-4PH Coil Stock | 0.08*200mm | Coil or Strip | Kgs | 1623 | Cold-Rolled+Annealed | Enquiry |

| 17-4PH Round Bar | Φ5-300mm*L | Round Bar | Kgs | 46958 | Hot-Rolled+Annealed+black | Enquiry |

| 17-4PH plate | 8-45*1200*3000mm | Plate or Sheet | Tons | 4.9 | Hot-Rolled+Annealed+black | Enquiry |

| Cr12MoV | 12-160(T)*310-610(W)*L | Plate or Sheet | Tons | 12.38 | Hot-Rolled+Annealed+black | Enquiry |

| 1.2601 | 12-160(T)*310-610(W)*L | Plate or Sheet | Tons | 11.22 | Hot-Rolled+Annealed+black | Enquiry |

| IncoloyA-286 / GH 2132 Stock | Φ8-65mm*L | Round Bar | Kgs | 489 | Hot-Rolled+Annealed+black | Enquiry |

| Incoloy800 round bar | Φ115*1400 | Round Bar | Kgs | 169 | Hot-Rolled+Annealed+black | Enquiry |

| 17-7PH / 631 Coil & Strip, Sheet Stock | 0.3-3.0*10-180mm | Coil or Strip | Kgs | 1236.22 | Cold-Rolled+Annealed | Enquiry |

| X22CrMoV12-1 / 1.4923 | Φ17mm | Round Bar | Kgs | 300 | Hot-Rolled+Annealed+black | Enquiry |

| 1.2083 Forged Plate | T:105-185mm*W:510*L | Plate or Sheet | Tons | 26 | Forged+QT | Enquiry |

| X22CrMoV12-1 / 1.4923 | Φ30mm | Round Bar | Kgs | 300 | Hot-Rolled+Annealed+black | Enquiry |

| 1.4882 strip/sheet/plate stock | 3.5x200x1000-2000mm | Coil or Strip | Kgs | 200 | Cold-Rolled+Annealed | Enquiry |

| SA-437 Grade B4B/SUS 616 /422 Forged Bar | Dia.160xL | Round Bar | Kgs | 2120 | Forged+QT | Enquiry |

| H13 Tool Steel | 50x710xL | Flat or Square bar | PCS | 4 | Forged+Annealed+black | Enquiry |

| 1.2344(H13/X40CrMoV5-1/Z40CDV5) Stock List | Dia.182mm - Dia.510mm | Round Bar | Tons | 120 | Forged+Annealed+black | Enquiry |

| 1.2344 ESR Round Bar Stock List(2019-9-3) | Select | 0 | Select | Enquiry | ||

| Stainless Steel 422 / Alloy 422 AMS 5655 UNS S42200/616/B4B Round Bar Stock | Select | 0 | Select | Enquiry | ||

| 1.2343 ESR Stock list(2019-09-03) | Select | 0 | Select | Enquiry |