NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti Enquiry | Print this page

AFNOR NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti Details

AFNOR NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti Standard Download

| Category | Type | Grade | Designations |

|---|---|---|---|

| Grades | Superalloys | NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti | France - AFNOR , AIR 9165 - |

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | 0.08 | 0.15 | ||

| Si | - | 1.00 | ||

| Mn | - | 1.00 | ||

| P | - | 0.015 | ||

| S | - | 0.015 | ||

| Cr | 18.00 | 21.00 | ||

| Ni | - | Bal | ||

| Co | - | 5.00 | ||

| Fe | - | 5.00 | ||

| Ti | 0.20 | 0.60 | ||

| Cu | - | 0.50 | ||

| Pb | - | 0.02 |

Mechanical properties of grade NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti AIR 9165

Yield Strength,Rp 0.2(MPa)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 240 | ||||

| Anneal Room ksi | 59.40 | |||

| Anneal 1000F ksi | 51.90 | |||

| Anneal 1200F ksi | 40.00 | |||

| Anneal 1400F ksi | 22 | |||

| Anneal 1600F ksi | 9.90 | |||

| Anneal 1800F ksi | 4.40 |

Tensile Strength,Rm(MPa)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 640 | ||||

| Anneal Room ksi | 114.40 | |||

| Anneal 1000F ksi | 105.60 | |||

| Anneal 1200F ksi | 69.30 | |||

| Anneal 1400F ksi | 41.40 | |||

| Anneal 1600F ksi | 20.20 | |||

| Anneal 1800F ksi | 9.70 |

Impact,Kv/Ku(J)

| Condition | Min | Max | Similar | Note |

|---|

Elongation,A(%)

| Condition | Min | Max | Similar | Note |

|---|---|---|---|---|

| 30 | ||||

| Anneal Room | 31 | |||

| Anneal 1000F | 27 | |||

| Anneal 1200F | 32 | |||

| Anneal 1400F | 75 | |||

| Anneal 1600F | 90 | |||

| Anneal 1800F ksi | 91 |

Reduction of area,(%)

| Condition | Min | Max | Similar | Note |

|---|

Hardness

| Condition | Type | Min | Max | Similar | Note |

|---|---|---|---|---|---|

| HB | 230 |

Related properties

| Forging conditions - Forging is made at a range of temperature included between 1150 and 950°C, then cooled at appropriate conditions for the final thermal treatment and obtain required characteristics. In any case, please contact us. |

| Properties / Main use conditions - This alloy is the "precursor" of refractory alloys with nickel base, it offers values to creeping until 800°C, together with an excellent resistance to corrosion at high temperature until 1100°C, especially in oxidizing ambiance. |

| Applications - Gas turbines, flame tubes, components for heat treatment ovens. |

| British Standard designation - HR5 + HR235 |

| Thyssen Krupp VDM designation - Nicrofer 7520 |

| Density - 8.37 |

Nickel and nickel alloy forgings - Ni-Cr Solid Solution Strengthened Alloy with good oxidation resistance at high temperatures.

The applications are mainly in Sheet form for Gas Turbine Engines and Industrial thermal processing, furnace components and heat treatment equipment.

Related Specifications

UNS 06075, BS HR5, BS2 HR504, BS HR403, BS HR203, NC20T, 2.4951, 2.4630, DIN 17752, DIN 17751, DIN 17742, ASTM B637, DIN 2.4631, DIN 2.4952, UNS N07080, BS4882 B80A, Alloy 80A, BS 3076 HR1, ASTM B 637, AECMA PrEn2188, AECMA PrEn2189, AECMA PrEn 2190, AECMA PrEn 2396, AECMA PrEn2397, AIR 9165-37, BS HR 601, BS HR1, DIN 17742, AFNOR NC 20TA, UNS N07080, Werkstoff Nr 2.4952, Werkstoff Nr 2.4631, NIMONIC 80a, MSRR 7095 and MSRR 7011, MSRR 7013, HR201, HR401, HR601, NA20, VAT80A

Studbolts and Nuts, Point Bolts, Engineer Waisted Studs, Engineer Studs, Hexagon Nuts, Hex Bolts, Socket Capscrews

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

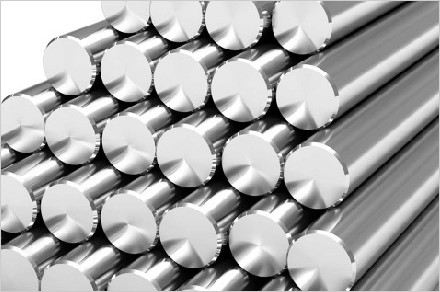

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

| Grade | Standard | Country | Application |

|---|---|---|---|

| NC20TA | AFNOR | France | Valve steels and alloys for internal combustion engines |

| NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti | AFNOR | France | Nickel and nickel alloy forgings |

| NiCr20Ti | B.S. | UK | Heat resisting steels and nickel alloys |

| 2.4951 | B.S. | UK | Heat resisting steels and nickel alloys |

| NiCr20TiAI | AFNOR | France | Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties |

| NiCr20Ti | ISO | International | Nickel and nickel alloy forgings |

| NiCr20TiAl | ISO | International | Heat-treatable steels, alloy steels and free-cutting steels -- Part 15: Valve steels for internal combustion engines |

| 1Cr18Ni12 | GB | China | Compared with 0 cr19ni9, processing low hardenability. Used for spinning processing, special drawing, cold heading |

| 0Cr23Ni13 | GB | China | Corrosion resistance and heat resistance are better than 0cr19ni9 |

| 0Cr25Ni20 | GB | China | Oxidation resistance is better than 0cr23ni13. Mostly used as heat resistant steel |

| 0Cr17Ni12Mo2 | GB | China | Seamless stainless steel tubes for boiler and heat exchanger |

| 1Cr18Ni12Mo2Ti | GB | China | Seamless stainless steel tubes for boiler and heat exchanger |

| 0Cr18Ni12Mo2Ti | GB | China | Seamless stainless steel tubes for boiler and heat exchanger |

| A-29 1025 | SAE | USA | General use carbon steel rod |

| 1025 | SAE | USA | These products have been used typically for use in fabrication of fittings, but usage is not limited to such applications. These products are not typically used for deep forming or cupping operations. |

| G10250 | AISI | USA | General use carbon steel rod |

| 1026 | YB | USA | Nonresulfurized carbon steels |

| G10260 | AISI | USA | This grade is a carbon steel composition applicable only to structural shapes (sections), plates, strip, sheets, and welded tubing. |

Relevant products

-

Nimonic 80A / NiCr20TiAl(2.4952) / UNS N07080/ BS 3HR1

-

SKD-11 Cold working die steel

-

X165CrMoV12 Cold working die steel

-

D2 Round Bar

-

P20 tool steel round bar

-

T30402/X155CrVMo121 Die Steel Sheet

-

1.4980 Round Bar

-

45Cr14Ni14W2Mo forging

-

D6AC Forging Hollow Bar

-

GH 3536 Sheet

-

UNS N10276 Coil

-

IncoloyA-286 / GH 2132

-

S66286 round bar

-

Inconel625 round bar

-

HastelloyC-22 round bar

-

NO8020 round bar

-

HastelloyC-276 round bar

-

Incoloy825 round bar

-

NO8825 round bar

-

Inconel825 round bar

NC20T, NiCr20Ti, N06075, 2.4951, NiCr20Ti Steel Stock

| Steel grade | Dimension | Shape | Unit | Quantity | Delivery state | Query |

|---|---|---|---|---|---|---|

| D2 Round bar | Φ25-Φ380mm | Round Bar | Kgs | 45325 | Hot-Rolled+Annealed+black | Enquiry |

| Cr12MoV | 12-160(T)*310-610(W)*L | Plate or Sheet | Tons | 12.38 | Hot-Rolled+Annealed+black | Enquiry |

| 1.2601 | 12-160(T)*310-610(W)*L | Plate or Sheet | Tons | 11.22 | Hot-Rolled+Annealed+black | Enquiry |

| IncoloyA-286 / GH 2132 Stock | Φ8-65mm*L | Round Bar | Kgs | 489 | Hot-Rolled+Annealed+black | Enquiry |

| X22CrMoV12-1 / 1.4923 | Φ17mm | Round Bar | Kgs | 300 | Hot-Rolled+Annealed+black | Enquiry |

| 1.2083 Forged Plate | T:105-185mm*W:510*L | Plate or Sheet | Tons | 26 | Forged+QT | Enquiry |

| X22CrMoV12-1 / 1.4923 | Φ30mm | Round Bar | Kgs | 300 | Hot-Rolled+Annealed+black | Enquiry |

| 1.4882 strip/sheet/plate stock | 3.5x200x1000-2000mm | Coil or Strip | Kgs | 200 | Cold-Rolled+Annealed | Enquiry |

| SA-437 Grade B4B/SUS 616 /422 Forged Bar | Dia.160xL | Round Bar | Kgs | 2120 | Forged+QT | Enquiry |

| 1.2344(H13/X40CrMoV5-1/Z40CDV5) Stock List | Dia.182mm - Dia.510mm | Round Bar | Tons | 120 | Forged+Annealed+black | Enquiry |

| 1.2344 ESR Round Bar Stock List(2019-9-3) | Select | 0 | Select | Enquiry | ||

| Stainless Steel 422 / Alloy 422 AMS 5655 UNS S42200/616/B4B Round Bar Stock | Select | 0 | Select | Enquiry | ||

| 1.2343 ESR Stock list(2019-09-03) | Select | 0 | Select | Enquiry | ||

| 1.2367 ESR Forged Round Bar stock(2019-09-03) | Select | 0 | Select | Enquiry | ||

| 1.2379 ESR Round Bar Stock(2019-09-03) | Select | 0 | Select | Enquiry | ||

| 1.2714 Hot-Work Mould Steel Flat Bar Stock(2019-09-03) | Select | 0 | Select | Enquiry | ||

| 1.2714 Stock list 2020-06-15 | Select | 0 | Select | Enquiry | ||

| 1.2344 Stock List 2020-06-15 | Select | 0 | Select | Enquiry | ||

| 1.2714 QT Bar Stock List 2020-06-15 | Select | 0 | Select | Enquiry | ||

| 1Cr11Ni2W2MoV,961,13Cr11Ni2W2MoV Sheet | Select | 0 | Select | Enquiry |